Cv 62 Aircraft Carrier - Copyright © 2023 by Mesothelioma.com. All Rights Reserved. The information contained on this site is proprietary and protected. Any unauthorized or illegal use, copying or dissemination will be prosecuted to the fullest extent of the law.

After decommissioning, the carrier remained in mothballs for five and a half years before being struck on March 8, 2004. During the time in mothballs, ex-Independence was said to have been heavily stripped to support the active carrier fleet, especially the Kitty Hawk

Cv 62 Aircraft Carrier

-class carriers. Her port anchor and both anchor chains were used on the new Nimitz-class carrier USS George H.W. Bush. The recycling of parts and the poor material condition of Independence at the time she was retired made a strong argument against retaining her as a potential museum ship.

Asbestos Use On Aircraft Carriers

In April 2004, U.S. Navy officials identified her as one of 24 decommissioned ships available to be sunk as artificial reefs. The companies who sold this asbestos to the U.S. Navy were typically aware of the threat it posed, but did nothing to warn the veterans who would be working with it.

This led to many veterans developing mesothelioma later in life; a disease only known to be caused by asbestos. Before sailing back to Yokosuka, Japan, the Indy made its last port call of the deployment to Hong Kong in May.

It was the last U.S. naval port visit to the territory before its reversion to China on 1 July 1997. In the summer of 1974, the Independence departed Norfolk for yet another 'Med Cruise', operating with CTF 60.1 and CVW-7.

On Sept. 8 Sailors were introduced to the new concept of terrorism when a bomb exploded in the cargo compartment of TWA Flight 841 high above. Steaming to the crash site, the Indy and other ships spent two long days retrieving what little remained of the ill-fated jetliner, her crew, and passengers.

Who Was At Risk Of Asbestos Exposure On Aircraft Carriers?

April 3, 1997 An F-18's wheel mount collapsed during a cat shot, the wing tip slamming shut a deck hatch on the legs of a crewman who was taken by an SH-60 helicopter to a hospital in Sydney, Australia.

The F-18 involved was damaged and was flown on 1 engine 220km to Williamtown RAAF base where it managed a landing with a wheel collapsing. Following training exercises, ranging north to New York and south to Mayport, Fla., USS Independence departed Norfolk Sept.

8, 1964, for NATO Teamwork exercises in the Norwegian Sea and off the coast of France, then to Gibraltar. The carrier returned to Norfolk Nov. 5 and entered the NNSY for overhaul. On November 19, 1980, USS Independence deployed to the Indian Ocean and was on watch on "Gonzo Station" as United States President Reagan took office and the Iranian hostages were freed.

Subsequently completing an Indian Ocean cruise, the aircraft carrier transited the Suez Canal northbound, shortly after USS America (CV 66) had transited southbound, making America the first U.S. Navy carrier (and, thus, Indy the second) to transit the Suez Canal since USS Intrepid (CV 11) in 1967. CV 62 completed a deployment of 204 days, during which the crew saw freedom only three times;

Uss Independence Cv-

5 days in Mauritius, a week in Perth, Australia, and a short half-day stop in Rota, Spain, before crossing the Atlantic to return to Norfolk on June 10, 1981. CVA 62 operated off the Virginia Capes for the next year on training maneuvers, and departed August 4, 1960, for its first cruise to the Mediterranean, ending the deployment March 3, 1961. The remainder of the year was spent in training and readiness operations

in the Atlantic Ocean. Because of faulty maneuvers, in the Caribbean Sea in March, the carrier collided with USNS Diamond Head (AE 19). USS Independence was not damaged, but two departments of the AE 19 had leaks and went full with water.

Individuals and their loved ones should contact a mesothelioma law firm to learn more about their legal options. In addition to lawsuits, victims may be eligible for other types of compensation. Mesothelioma lawyers understand state legal deadlines and may help their clients gather evidence needed to file a claim or lawsuit.

Until the late 1970s, many aircraft carriers were constructed with ACMs. Asbestos was commonly used to fireproof pipes that carried steam and hot liquids. During maintenance and repair of these products, asbestos fibers were often released into the air.

One of the newest class of "supercarriers" at the time of her commissioning, USS Independence conducted shakedown training in the Caribbean and arrived at her homeport of Norfolk June 30. On Aug. 25, during suitability trials on board the Indy, an A3D Skywarrior, piloted by Lt.

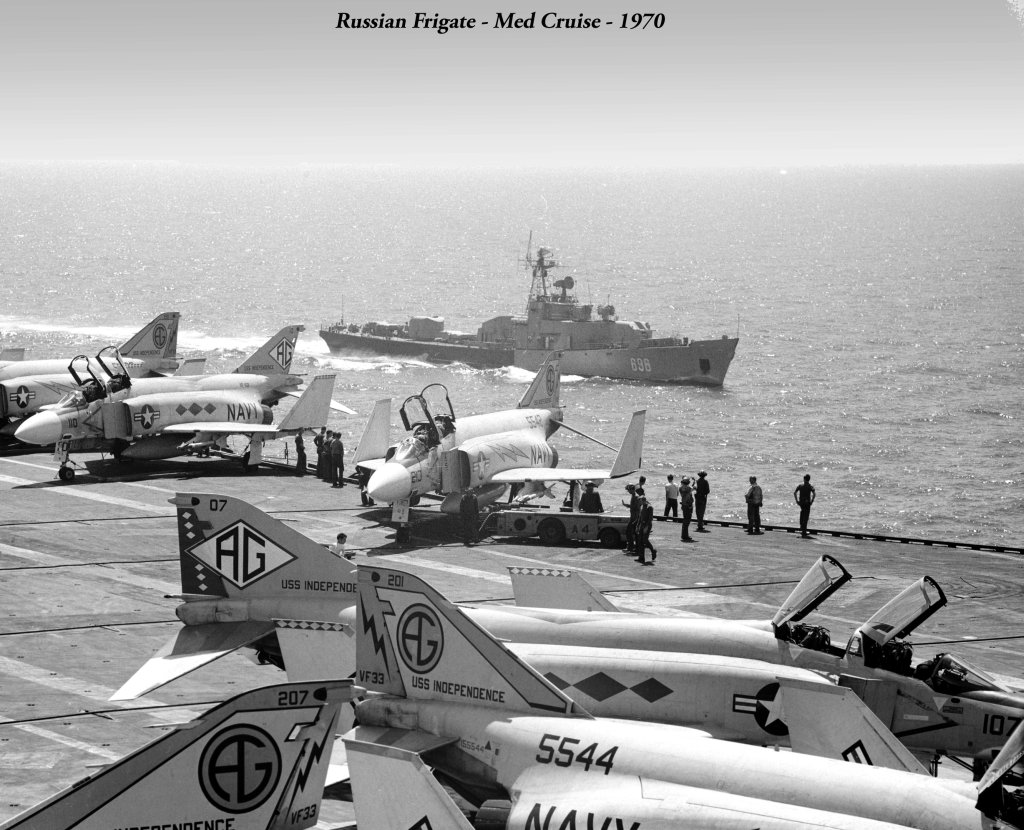

Cmdr. Ed Decker, took off at a gross weight of 84,000 pounds - the heaviest aircraft ever to take off from a carrier. USS Independence was again deployed to the Mediterranean on June 23, 1970, returning to Norfolk Naval Base January 31, 1971. It was during this cruise that Indy was awarded the Meritoreus Unit Commendation in support of actions against the PLO during the Jordanian crisis.

USS Independence departed Norfolk August 6, 1963, to take part in combined readiness exercises in the Bay of Biscay with sea-air units of the United Kingdom and France then entered the Mediterranean Sea Aug. 21 for further duty with the Sixth Fleet.

Cruising throughout the Med, she gained much valuable experience during combined NATO exercises, including close air support to Turkish paratroops, reconnaissance, communications, and convoy strike support. President Makarios of Cyprus paid her a visit Oct. 7, after which she joined in bilateral U.S.-Italian exercises in the Adriatic Sea with Italian patrol torpedo boats, and U.S.-French exercises which pitted her aircraft against French interceptors and a surface action with French cruiser Colbert (C 611).

The Indy returned to homeport March 4, 1964. Ships built between the 1930's and 1970's commonly used asbestos in their construction, placing those who served aboard the USS Independence at a high risk of exposure. Asbestos could be found in equipment such as boilers, turbines, valves, pumps, and electrical components.

At the time, asbestos was the principal insulating material for the U.S. Navy's high-pressure steam valves. In the 1940s, the Navy began documenting the connection between asbestos exposure and a number of illnesses. Despite knowing asbestos was dangerous, the Navy continued to put individuals on the USS Independence at risk of developing an asbestos-related disease.

Many individuals have experienced occupational asbestos exposure on aircraft carriers. Navy personnel and shipyard workers were at risk of exposure while cutting, sawing and handling asbestos products. During these processes, asbestos was often released into the air.

Victims of asbestos exposure have a right to seek compensation. Those diagnosed with mesothelioma or other asbestos-related diseases can have the often overwhelming costs of medical care covered by settlements, and may be entitled to additional sums for pain and suffering.

In 1997, CV 62 made a four-month deployment, covering several major exercises and seven ports of call. Included in these ports of call were two historic port visits. The first was Feb. 28 to the island territory of Guam.

The Independence was the first aircraft carrier to pull into Guam in 36 years. The second, two months later, was to Port Klang, Malaysia. USS Independence became the first carrier in the world to make a port visit to Malaysia.

The Navy's first aircraft carriers were also constructed with a variety of asbestos-containing products. Due to the mineral's durability and heat resistance, asbestos was a popular material in Navy ships. Asbestos was commonly used to fireproof and insulate steam pipes, turbines and valves.

Military veterans with asbestos illnesses may also be eligible for benefits from the U.S. Department of Veterans Affairs. By filing a VA claim, veterans may receive financial compensation. Veterans may also seek treatment for asbestos illnesses at VA hospitals.

In August 1990, with Carrier Air Wing Fourteen embarked, USS Independence was sent to deter Iraqi aggression during Operation Desert Shield. Arriving on station in the Gulf of Oman on August 5, she was the first aircraft carrier to enter the Arabian Gulf since 1974. The Indy remained on station for more than 90 days and permanently reestablished a U.S.

naval presence in the region. The ship returned to San Diego December 20. Materials such as gaskets and packing were also often made of asbestos. A high concentration of these items were located in the engine and boiler spaces of ships, putting Machinist's Mates, Boiler Tenders, Firemen, and others who worked in these areas in the most danger.

Notice: This website and its content are sponsored by Early, Lucarelli, Sweeney, & Meisenkothen, LLC, a law firm specializing in asbestos injury litigation. Attorney Advertising. Prior results do not predict a similar outcome. Please read our disclaimer for more information.

The USS Independence was the final ship constructed in the Forrestal class of aircraft carriers. In 1959, the Navy commissioned the USS Independence as an attack aircraft carrier. The ship was later redesignated as a multi-purpose aircraft carrier.

In 1982, USS Independence provided critical support to the multinational peacekeeping force in Lebanon. On June 25, the greatest concentration of U.S. Navy air power in the Mediterranean Sea resulted when the battle groups of the Forrestal (CV 59) and Independence joined forces with the Dwight D. Eisenhower (CVN 69) and John F. Kennedy (CV 67).

In 1922, aircraft carriers were first adapted from other Navy vessels. The Washington Treaty of 1922 limited the number of battleships and cruisers the U.S. Navy could have. This led the U.S. Navy to convert two battlecruisers into the first aircraft carriers.

USS Independence changed homeports again on September 11, 1991 to Yokosuka, Japan, embarking Carrier Air Wing Five and becoming the Navy's only permanently forward-deployed aircraft carrier and flagship for Commander, Carrier Group Five. For years, the man worked as a pipe coverer and pipefitter at Newport News Shipbuilding and Drydock Company.

The man spent time insulating pipes and valves on the aircraft carrier USS America. He also installed and removed pipes aboard several submarines. During these jobs, he experienced asbestos exposure. On October 25, 1983, aircraft from USS Independence's embarked air wing flew missions in support of Operation Urgent Fury, the action to liberate the Caribbean nation of Grenada.

Returning to Lebanon that same year, the ship's air wing conducted air strikes against Syrian positions. Asbestos was also commonly added to parts in jets, airplanes and helicopters. Individuals who service aircraft may have come in contact with asbestos-containing brakes and other automotive parts.

As a result, service members were put at risk of asbestos exposure. USS Independence became the oldest ship in the U.S. Navy's active fleet, and the first carrier in history to hold that distinction, on June 30, 1995. With this honor, the Indy displayed the Revolution-era First Navy Jack, commonly called the "Don't Tread On Me" flag, from

her bow until her decommissioning. The flag was presented to the ship's CO Capt. David P. Polatty III in a formal ceremony on July 1. The flag was received from USS Mauna Kea (AE 22) upon her decommissioning.

On February 17, 1985, USS Independence arrived at the Philadelphia Naval Shipyard to undergo a modernization and overhaul program to extend her service life by 15 years. The flight deck was improved to allow the recovery of high-performance aircraft while the ship traveled at slower speeds, and the NATO Sea Sparrow launchers were upgraded.

Other improvements improved the ship's fuel consumption. CV 62 completed the Service Life Extension Program (SLEP) at Philadelphia Naval Shipyard in June 1988. Setting sail Aug. 15 from Norfolk, the ship transited the tip of South America and arrived at her new homeport of San Diego, Calif., Oct.

8. Until the late 1970s, asbestos was commonly used by the U.S. Navy to insulate pipes, turbines and other materials. For example, two aircraft carriers built with these asbestos-containing materials (ACMs) were the USS Kitty Hawk and the USS Independence.

Aircraft carriers are warships equipped with flight decks capable of transporting aircraft. Until the late 1970s, shipbuilders constructed United States aircraft carriers with many asbestos materials. Widespread asbestos use on aircraft carriers caused many individuals to experience exposure.

As a result, Navy veterans are at a high risk of developing mesothelioma.

uss independence cv 62 history, uss cv 62, uss independence aircraft carrier, uss independence carrier, uss independence vietnam service, cv 50 aircraft carrier, cv 62 independence, cv 44 aircraft carrier